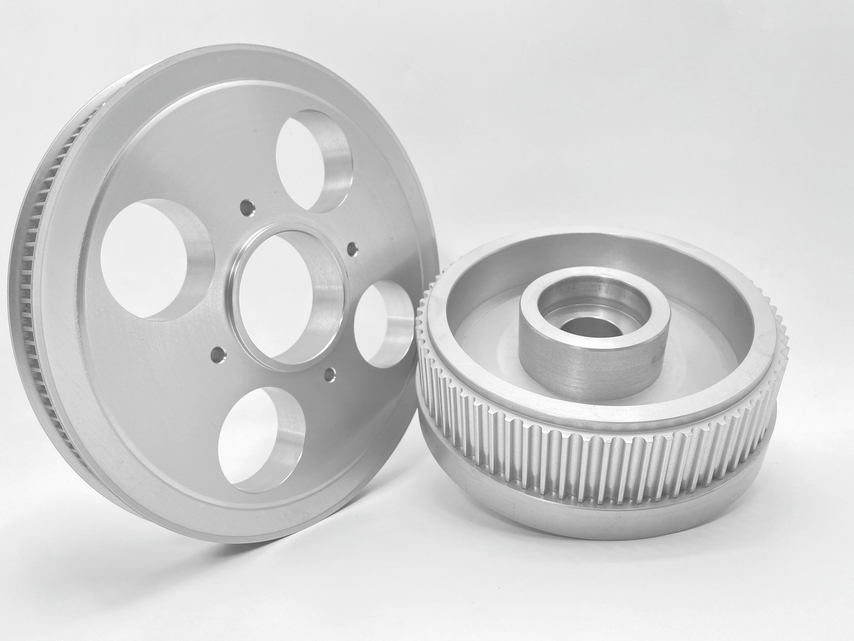

Advantages: Lightweight, corrosion-resistant, and aesthetically pleasing

Disadvantage: Hardness less than 45 # steel

General materials: 6061, 2A12, 7075

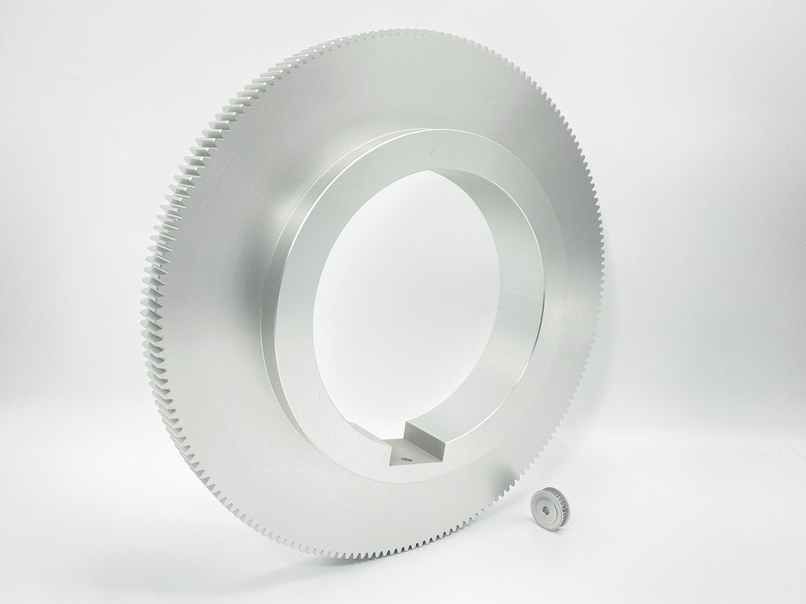

Synchronous pulleys are generally made of materials such as steel, aluminum alloy, cast iron, brass, etc. The inner hole has various forms such as circular hole, D-shaped hole, conical hole, etc. Surface treatment includes natural color oxidation, blackening, galvanizing, color zinc plating, high-frequency quenching, and other treatments. The accuracy level is determined by customer requirements.

The use of aluminum alloy synchronous pulleys

The synchronous pulley allows for operation in environments with pollution and harsh working conditions. For example, in mechanical manufacturing, automotive and aircraft, textile, light industry, chemical industry, metallurgy, mining, military industry, instruments, machine tools, agricultural machinery, and commercial machinery transmission.

Characteristics of aluminum alloy synchronous pulley

(1) Accurate transmission, no sliding during operation, with a constant transmission ratio;

(2) Smooth transmission, with buffering and vibration reduction capabilities, and low noise;

(3) High transmission efficiency, up to 0.98, with significant energy-saving effect;

(4) Convenient maintenance, no need for lubrication, and low maintenance costs;

(5) The speed ratio range is large, usually up to 10, and the linear speed can reach 50m/s, with a large power transmission range of several watts to several hundred kilowatts;

(6) Can be used for long-distance transmission, with a center distance of over 10m;

(7) No pollution, can work normally in places where pollution is not allowed and the working environment is relatively harsh.

Advantages of aluminum alloy synchronous pulley

Synchronous belt wheel drive is composed of a closed circular tape with equidistant teeth on the inner surface and corresponding pulleys. When in motion, the teeth of the belt mesh with the grooves of the synchronous belt wheel to transmit motion and power, which is a meshing transmission and therefore has various advantages of gear transmission, chain transmission, and belt transmission.

Synchronous belts can be divided into chloroprene rubber and fiber rope synchronous belts and polyurethane and steel wire synchronous belts according to their materials. Currently, they are mainly divided into two categories based on the shape of the teeth: trapezoidal teeth and circular arc teeth. According to the arrangement of the teeth, they can be further divided into single-sided tooth synchronous belts and double-sided tooth synchronous belts. Synchronous belt transmission has accurate transmission ratio, no slip, can achieve a constant speed ratio, can achieve precise transmission, smooth transmission, can absorb vibration, low noise, and a wide range of transmission speed ratios, generally up to 1:10. The allowable linear speed can reach 50m/s, and the transmission efficiency is high, generally up to 98% -99%. Transfer power from a few watts to hundreds of kilowatts. The compact structure is also suitable for multi axis transmission, with low tension, no need for lubrication, and no pollution, so it can work normally in situations where pollution is not allowed and the working environment is relatively harsh.